Industrial robotics are a crucial part of modern manufacturing, aiding in tasks like assembly, packing, production, inspection, and labeling, to name a few. Thanks to its ability to automate repetitive, tedious tasks, industrial robotics is eliminating the need for massive human labor — with over 3.4 million robots placed across factories in the world today.[1]

Since these robots have piles of data to analyze on the go, they require fast and reliable storage solutions to ensure optimal performance. This is where a NAND flash SSD comes in, delivering high-speed data to help robots process information swiftly. Read on to learn more about the advantages of a NAND flash SSD.

Technical Advantages of NAND Flash SSDs

1. Speed and Efficiency

A NAND flash SSD has high read and write speeds (540-550 MB/s) compared to a traditional hard disk drive (HDD), facilitating real-time processing in industrial robotics.[2] Plus, since an SSD has no moving parts, it consumes less power during operation (2-5 watts), which results in less heat generation in factories and warehouses.[3]

2. Capacity

With a storage capacity ranging from 128 GB to 4 TB, a NAND flash SSD is a preferred choice for addressing various industrial robotic needs. Plus, compared to traditional storage options, these drives can be manufactured in small-sized chips with higher capacities.

3. Durability

Some SSD products are labeled as “Industrial Grade,” which means that they’re designed to support the rigorous range of temperatures in factories, usually ranging from -20˚C to 75˚C or -40˚C to 85˚C. Due to this, a NAND flash SSD is suitable for operations even in harsh conditions, like automotive systems, manufacturing plants, and outdoor installations.

4. Data Transfer

Apart from durability in industrial settings, a NAND flash SSD usually relies on high-speed protocols like NVMe (Non-Volatile Memory Express). These substantially improve data transfer rates and help industrial bots access stored information quickly (reducing latency). Plus, NAND flash SSDs use multi-lane support and parallelism, which allows for data transfer between multiple streams and quicker read/write operations.

5. Data Security and Management

Unlike HDDs, NAND flash SSDs don’t have mechanical components susceptible to failures, reducing the risk of data loss. Plus, these storage drives come with advanced security features that protect sensitive information, like Quick Erase.

Challenges in Industrial Robotics and SSDs’ Role

1. Handling Massive Data Processing Needs

A NAND flash SSD uses flash memory to store data, eliminating the need for moving parts found in traditional HDDs. This helps access and retrieve massive data bundles at a much faster rate, which is crucial in industrial settings requiring quick decision-making.

2. Environmental Resilience Needs

Industrial environments often have a demanding nature, with things like temperature variations, dust, and vibrations impacting the SSD performance. However, an industrial SSD eliminates this risk due to the lack of spinning disks.

3. Consistent Operations and Uptime

SSD storage systems usually consume less power than HDD counterparts, which leads to lower energy requirements. In addition, a NAND flash SSD stores data electronically on cells, resulting in swift retrieval and real-time processing.

4. Scalability and Flexibility in Robotics

Since SSDs use semiconductor chips, they retrieve data much quicker — making the industrial robots highly responsive and efficient. Plus, the use of 3D TLC NAND addresses the scalability concerns in manufacturing units. Unlike the 2D or planar technology, where memory cells are arranged in a single layer, 3D NAND flash involves stacking these cells vertically. This allows for increased storage capacity for your industrial needs.

5. Securing Data in Industrial Robotics

Given the interconnected nature of industrial settings, many struggle with maintaining the integrity and safety of their data systems. However, SSDs transcend these challenges through the use of Advanced Encryption Standard (AES) encryption. This method ensures that your data remains safe and sound by using a cryptoprocessor on the drive.

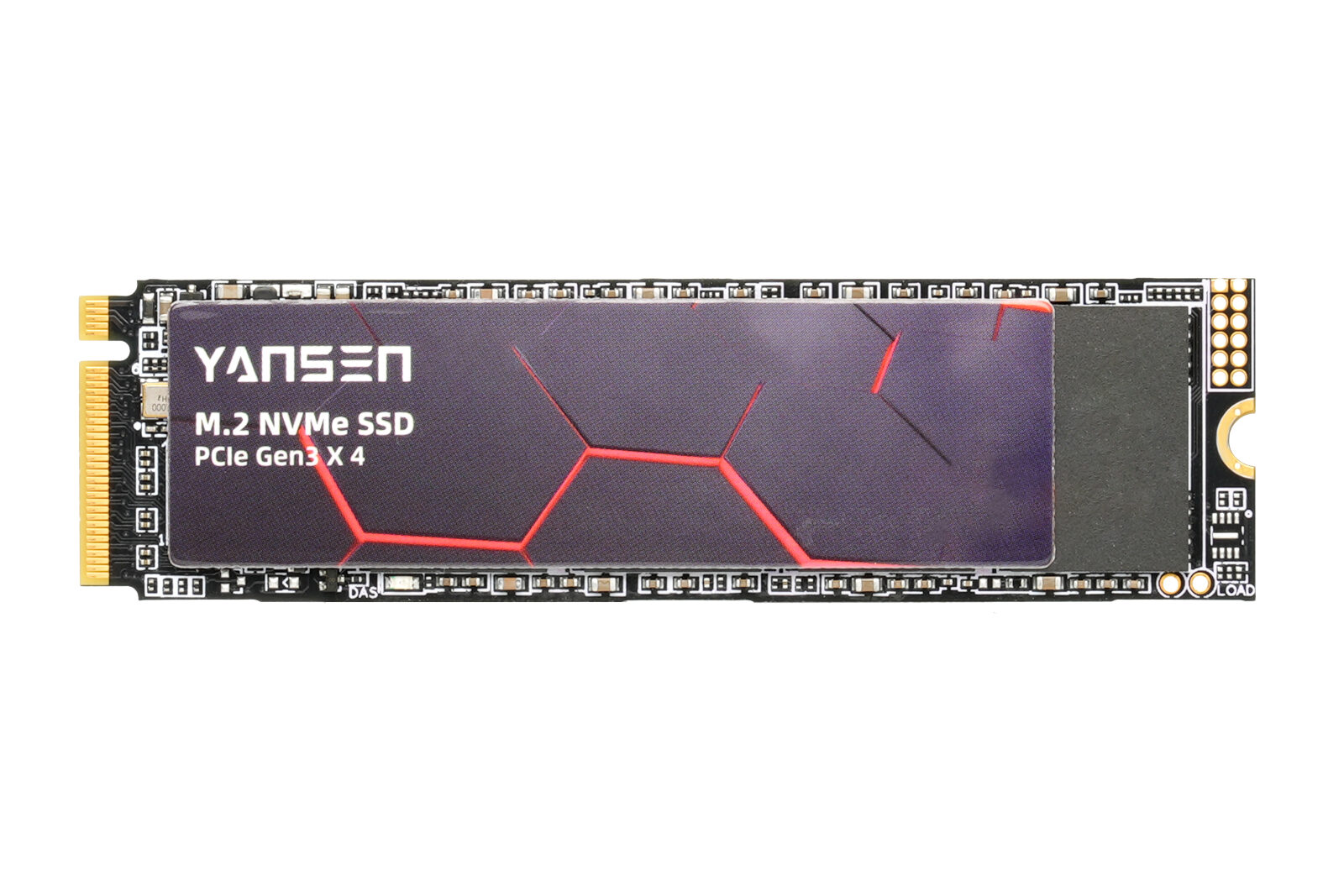

Introduction to YANSEN YSINXXX-M430 2280 SSD

The YANSEN YSINXXX-M430 2280 is a high-performance M.2 PCIe SSD that offers efficient storage solutions. With capacities ranging from 128GB to 2TB, this SSD uses 3D TLC NAND technology, processing your data within minutes. Plus, it comes with a PCIe Gen3 x4 interface providing maximum read and write speeds of 3500 MB/s and 3000 MB/s.

Applicability in Industrial Robotics

When it comes to industrial robotics, the YANSEN YSINXXX-M430 2280 answers all your storage-related woes. Equipped with a high-speed data transfer capability, the SSD can withstand a temperature range of 0℃ to 70℃. Plus, it is compatible with NVMe 1.4, so there’s no doubt about the efficiency.

Conclusion

The importance of NAND flash SSDs in industrial robotics cannot be overstated. These storage devices improve the overall performance and efficiency of robotic systems by providing quick, reliable access to data. Plus, they make your robots more responsive by facilitating on-time decision-making and swift operations.

As technology advances, the demand for faster and more efficient data solutions is likely to grow. This means that NAND flash SSDs will become more popular, providing an excellent speed-to-efficiency ratio, which is crucial in robotics.

Reference

[1] Robotics Industry Stats & Trends (2023). Available at:

https://explodingtopics.com/blog/robotics-industry-stats (Accessed: January 30, 2024)

[2] SSD vs. HDD Speeds: What’s the Difference? Available at:

https://blog.purestorage.com/purely-informational/ssd-vs-hdd-speeds-whats-the-difference/ (Accessed: January 30, 2024)

[3] SSD or HDD Hard Drives. Available at:

https://www.intelice.com/ssd-or-hdd-hard-drives/ (Accessed: January 30, 2024)